Available from Stock or Manufactured to Specific

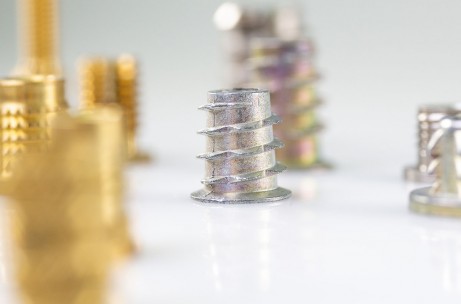

At Crown Screw we understand the critical role that our Inserts play in the manufacture of your products. From high volume automotive customers, local fabricators, moulders to low volume prototyping, we will have the precise components for your requirements. This information page is designed to give you a brief overview into the world of inserts for plastics, to guide you towards the right component for your project. Inserts For Plastics Our range of Inserts for plastics provide a fast, efficient and strong way to enable a female threaded fastener into plastics. Inserts can be moulded, screwed, heated, cold pressed or ultrasonically inserted into your desired plastic moulding, ready for further assembly options. This range of inserts has been specifically designed to offer a secure fix by mating with a matching threaded screw, securely clamping multiple work pieces together. Perfect for applications that require to be assembled and dismantled time and time again, minimising damage to the moulding. Due to the insertion process you can expect to see high jack out loads and torque values, dependant on the variant being used. Most commonly used in the automotive and injection moulding industries and are available in various body styles, bore dimeters, materials and finishes. If a special is required, we can manufacture to your specific requirements.

Range: Mould In Inserts, Screw In Inserts, Self Tapping, Heat Fit Inserts, Cold Press In Inserts, Ultrasonic Inserts, Self Locking

Body Styles: Round, Hex, Square, split body, Knurled

Head Styles: Headed, Un-headed Threads: Metric, Imperial

Materials: Steel, Stainless Steel, Brass

Finishes: Self Colour, Zinc Plated, staylack, Ford & JLR spec coatings to WX100

Mould In Inserts

Mould in inserts are a popular range with manufactures that have their own injection moulding machines, enabling them to introduce the inserts to pins situated in the cavity prior to the moulding process. At this stage the cavity is closed, and material fills the cavity securing the inserts in place and eliminating the process of second operation insertion. Headed an un-headed variants are available in a variety of threads and lengths. If a special is required, we can manufacture to your specific requirements.

Screw In Inserts / Self Tapping

Screw in inserts are popular with manufactures that are looking for high pull out forces, faster installation and have the ability to be used in a wide variety of material from plastics, steel castings, Aluminium and wood. This range of inserts not only has internal threads but also have external threads, cutting slots and bores that assist with the self tapping feature. Headed an un-headed variants are available in a variety of threads and lengths. If a special is required, we can manufacture to your specific requirements.

Heat Fit Inserts / Ultrasonic

Heat fit inserts generally have opposing knurl bands on the outer dimeter, that once heated or ultrasonically embedded into position, will act as a locking feature that will maximise torque out and give them a secure hold. This range of inserts tends to have a one-way installation fix. but double ended inserts are also available for faster auto fed projects. A great multi purpose all rounder. headed and un-headed variants are also in a variety of threads and lengths along with studs, if you’re looking for a heat fit male threaded fastener solution. If a special is required, we can manufacture to your specific requirements.

Cold Press In Inserts

Cold press inserts are popular for their user-friendly feature as you would only require a small press to install. Unlike the above inserts, this range generally only has a single direction knurl band or bands that assist with easy installation. Cold press inserts would not be able to match the torque out figures that could be achieved with the above ranges. Headed and un-headed variants are also in a variety of threads and lengths along with studs if you’re looking for a heat fit male threaded fastener solution. If a special is required, we can manufacture to your specific requirements.

Self Locking

Self locking inserts are known for their quick and easy installation. Rather than using knurl bands this range of insert is made up of split body with barbs on the outer diameter. Once the insert is in place in the mating material a screw can then be driven into the insert, opening the body slightly and firmly locking the barbs into the plastic, creating a firm hold. A great option if you’re looking for an insert that will be suitable to assist with anti-vibration with high load capacity. Headed and un-headed variants are available in a variety of threads and lengths. If a special is required, we can manufacture to your specific requirements.

Why Choose Crown Screw?

At Crown Screw, we take pride in offering an extensive selection of fasteners, components and services. Our commitment to quality and precision ensures that our products meet the most demanding industry standards. We are not just suppliers; we are your partners in finding the right solutions for your unique requirements.

Comprehensive Selection - Commitment to Precision - Tailored Solutions - Excellence & Reliability

About UsAt Crown Screw, our mission is to provide you with the highest quality fasteners, components, and services tailored to your needs. Whether you're looking for the perfect fasteners for your project, need assistance with component selection, or require expert advice on services, our dedicated team of experts is here to help.

Expert Guidance - Exceptional Customer Service - Costings and Logistics - Seamless Shipping

Make An Enquiry