Additional Specifications to Enhance Performance

Offering a range of additional services that may be required to maximise and enhance the performance of our fixings, through thread patching, thread masking and plating.

At Crown Screw we understand the critical role that our fasteners play in the manufacture of your products. Sometimes our products need to meet additional specifications to enhance performance. From thread patching, thread masking to additional plating requirements, these are all areas that can be supported. From high end automotive customers, fabricators to prototyping and beyond, we will not only have the precise components and tools for your build, but we are keen to support with any additional enhancing services that may be required, offering an all under one roof service from enquiry to production. This information page is designed to give you a brief insight into the world of other services that we offer.

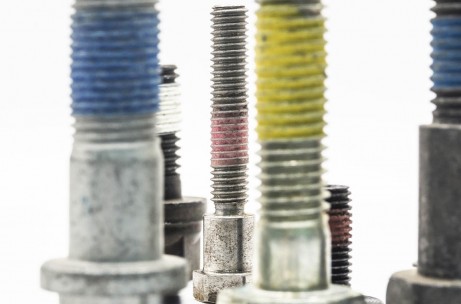

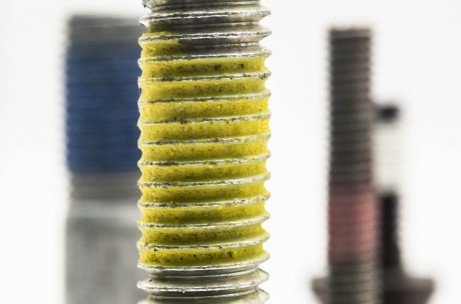

Thread Patching

Crown Screw strive to look after our customers in all areas of business. By offering an all under one roof service, we can work together to make sure all of your fasteners meet specification, by the addition of thread patching or sealant features to solve anti-vibration issues or simple thread locking requirements. We can offer a range of thread patching and sealants, dependant on the fixing/assembly that you are wishing to use. Our team can assist with any enquiry for thread patching and sealants, offering a fast turn around service with competitive pricing. This service is widely used in many market sectors thought manufacturing.

Range:

- 180° Thread Patch.

- 360° Thread Patch.

- Variable Patch length and positioning available.

- Anti vibration.

- Standard or High Temperature applications.

- Nylon Patches.

- Precote Patches.

- Colour coding patches.

- Thread sizes from M1 to M30.

Masking

We now hold stock of thread masked weld nuts, as this has become a popular product with welding teams throughout the industry. By offering this service you are guaranteed that weld spatter will not adhere to the thread, and post weld plating applied to a final assembly will not cover the thread either, be it male or female. This is widely used in the automotive and fabrication sectors.

Benefits

- Prevents adhesion of weld spatter to the thread source

- Prevents adhesion of additional coatings to the thread source.

- Can be applied to male and female threads.

- Reduces down time and manufacturing costs.

- Reduces risk of scrap assemblies.

- Affordable & Efficient.

- Thread caps and plugs not required.

LATEST FROM CROWN SCREW

Stay updated with the latest in the fastener industry by subscribing to our newsletter. Join our community of professionals, engineers, and enthusiasts who rely on Crown Screw for expert insights, product updates, and exclusive offers.

Read Our Privacy Policy